+86 18660512269

+86 18660512269

+86 18660512269

+86 18660512269

Shortcut Menu

Quality assuranceImproving production effeicency through Analysis of particle size for powder coating

The ingredients for powder coating are basically epoxy resin and polyester resin. These function as a matrix and binding agents for solid particles, and they also harden the finish. Special effects, such as matt finish, high polish, metallic look and pearl luster effect, are created with the use of several additives, aggregates and fillers; these can also produce durable surfaces that are repellent to dirt and resistant the environment.

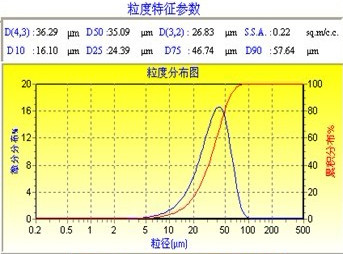

The function and processing properties of powder coating are defined by particle size distribution. Regular analysis of particle size distribution ensures the powder coating quality. Prompt analysis with high-frequency laboratory or process analysis in real time help to optimize the time and energy consuming grinding processes.

The trend diagram presents the particle sizes x10, x50 and x90. The evolution of size indicated is related to the classifier speed of the mill-classifier. The higher the classifier speed the finer the particles .

The control of the particle size distribution is crucial for both economic processing operation and for the final paint surface quality. The ideal distribution would be narrow – between 10 µm and 90 µm.

Process control and machine adjustment during production is necessary . continuous information about the particle size guarantees a complete quality monitoring in real-time. Adjustments of process variables, such as classifier speed, and their impact on particle size are tracked concurrently making process control much more intelligible. With an improved process understanding, any production may realise a significant reduction in out-of-specification batches.

For more information, please send us one email or call us .